Custom-made dye

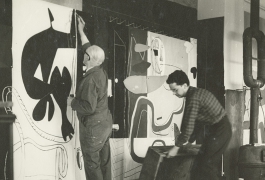

Opposed to industrial dyeing process, the craftsman-dyer works by hand, using visual trichromatic printing: he creates the desired shade by adding progressively in small doses the powdered pigments of primary colors (blue, yellow and red), without any machine.

In Aubusson, the dyer carries out a real research on shades, which he produces in small amounts. This small production of very specific tints corresponds to the needs of the low warp weaving.

In the case where the artist numbers its cartoon after a range of pre-dyed wools, the work of the dyer is simplified. His new dye will be applied on a material (wool) equal to the basic sample.

But when the artist produces a colored sample on paper or canvas, the task of the dyer becomes more delicate. He will measure the difference between a color (gouache or oil) and a dyeing product on a material such as wool.

Some even call them “colorist”, as the precision of the dyer allows him to reproduce exactly the tint looked for by the weaver or the artist.

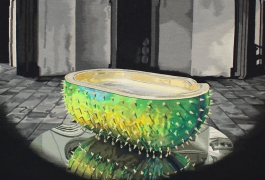

According to the demand of the artistic creation, the colorist can put forward a palette of almost infinite tints, made of the pigments of the three primary colors only: blue, red and yellow.

The craftsman only trusts his eye, his experience with chemical reactions and his steady hands to obtain the desired colors. He is the only judge when it comes to adding colorants, bit by bit, and of the “cooking” time: his expertise must guaranty the longevity of the color over time.

Dyeing workshops can be found within great weaving manufactures, but most of them call on a craftsman-dyer or a spinning mill, which has a dyeing workshop available.