Emplois et Stage

Offre d'emploi

La Cité internationale de la tapisserie recherche un.e Responsable de la communication

Durée : Recrutement statutaire fonctionnaire de catégorie A de la Fonction publique territoriale ou, à défaut, CDD de 3 ans renouvelable, avec prise de fonction fin 2023

Profil : Le/la candidat.e doit impérativement disposer d'au moins une expérience professionnelle réussie (hors stage) en matière de montage / pilotage / réalisation de projets dans le domaine de la communication, pour le compte d'une structure publique ou privée (idéalement dans le secteur artistique et/ou culturel).

Missions : Mise en place d'un plan de communication global incluant le déploiement des actions sur les réseaux sociaux, rédaction et conception de documents de promotion, suivi des relations presse, accompagnement de la stratégie de partenariats et de mécénat, ...

Candidature : Un CV et une lettre de motivation sont à adresser avant le 15 novembre 2023 à : Emmanuel GERARD, Directeur

Syndicat Mixte de la Cité internationale de la tapisserie et de l'art tissé

Rue des arts - 23200 AUBUSSON

Tél : 05 55 66 66 66

Courriel : contact@cite-tapisserie.fr

Offre de stage

La Cité internationale de la tapisserie recherche des stagiaires pour le Centre de Ressources - Bibliothèques des Arts André Chandernagor :

Durée : 2 mois minimum - stage conventionné (à partir du mois de janvier 2024)

Temps de travail : 35h

Profil : Etudiant en licence 3 ou Master dans le domaine de la documentation – sciences de l’Information et des Bibliothèques

Une première expérience en recherche, documentation, archives ou conservation des documents, métiers du

livre, histoire de l’art, anthropologie, ethnologie serait appréciée.

Mission : La mission consistera à se familiariser et à participer aux activités polyvalente d’un centre de ressources dans

un établissement muséal

Candidature : CV + LM

Possibilité de bénéficier d’un logement en colocation

Candidature et demande d’information : Emilie SZYMSKI, Documentaliste / Christophe JAMOT, Chargé de mission

Syndicat Mixte de la Cité internationale de la tapisserie et de l'art tisséRue des arts - 23200 AUBUSSON

Tél : 05 55 66 66 66

Courriel : contact@cite-tapisserie.fr

Discover

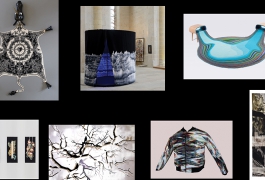

Outdoor tapestries

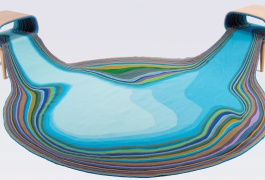

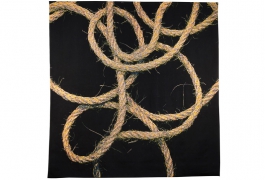

Les verdures emblématiques de la tapisserie d’Aubusson créent des jardins d’intérieur intégrés à l’architecture. Le programme de recherche "Tapisserie d’extérieur" prend le contrepied de la tradition et amène la tapisserie dans l'espace public, les parcs et les jardins.

En prenant appui sur les trois grandes fonctions originelles de la tapisserie – l’isolation, la communication et la décoration –, le programme de recherche "Tapisserie d’extérieur" se propose de renverser cette approche traditionnelle pour mener une réflexion sur la création d’une œuvre de tapisserie destinée à l’univers des parcs et jardins et, par extension, à l’espace public.

Ce programme est un moyen de stimuler l’innovation, dans une logique d’expérimentation et de recherche autour du savoir-faire pluriséculaire, pour aboutir à de nouvelles créations. Il permet de mener une réflexion d’ensemble en termes de contexte d’usage et de matériaux. Avec les innovations constantes en matière de textiles intelligents, le champs des applications possibles s'élargit chaque jour.

C’est dans cet esprit que la Cité de la tapisserie lance en 2013 un workshop à destination d'étudiants, faisant de l'innovation un levier important du renouveau de la perception de l'objet tapisserie aux yeux du grand public. Cet atelier constitue également une occasion importante d'inscrire la tapisserie d’Aubusson dans le pôle d’excellence arts textiles Rhône-Alpes/Auvergne/Limousin.

L’opération "Tapisserie d’extérieur", soutenue par le programme européen Leader, consiste dans l’élaboration de projets expérimentaux menés par les élèves de l’École Supérieure d’Art et de Design de Saint-Étienne (ESADSE) et du Diplôme Supérieur en Arts Appliqués du Lycée Raymond Loewy de La Souterraine, soit une cinquantaine d’étudiants. En juin 2013, les étudiants présentent leurs travaux et trois projets sont primés par le jury : le binôme Jean-Bastiste De Azevedo et Matthieu Mawlanazada (La Souterraine), Cédric Delehelle (La Souterraine), ainsi que Gwendoline Del Campo (Saint-Etienne).

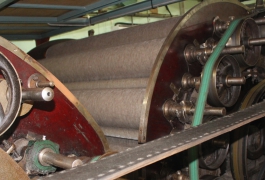

Ces projets servent alors de point de départ à l'identification des qualités nécessaires aux matériaux pour un tissage selon les techniques de basse-lisse traditionnelles à Aubusson : résistance à la traction pour supporter la tension entre les "ensouples" avant et arrière du métier à tisser ; souplesse de la fibre pour permettre la torsion et l'enroulement puis le tissage ; résistance au cisaillement ; élasticité faible pour éviter les problèmes de "flêche" (déformation de la tapisserie lors de son exposition ou de la chaîne lors du tissage) ; durabilité dans le temps...

À ces paramètres s'ajoutent ceux impliqués par l'exposition des œuvres tissées en extérieur: résistance aux U.V. (lune et soleil) ; tenue aux intempéries ; résistance mécanique accrue (vent, vandalisme)...

La Cité décide de lancer le tissage d'un prototype à partir du projet de Cédric Delehelle, Inter Spinas Floret. La fabrication et la teinte des fils a été confiée au Groupe Payen, leader européen des fils et tissus élastiques basé en Ardèche. Après une phase d’étude technique, le polyester texturé a été retenu. Le tissage de ces fibres particulièrement difficiles à manipuler a été assuré par l'atelier Patrick Guillot (Aubusson).